Sustainable Solutions for Lab Water Management: Compliance, Treatment, and Conservation

Laboratories play a critical role in advancing scientific discovery, but they also face unique challenges when it comes to managing water and wastewater systems. Understanding the regulatory framework governing wastewater discharge, implementing effective treatment processes, and adopting sustainable water-saving practices are essential for ensuring compliance and minimizing environmental impact.

John Rattenbury, PE, CPD, ARCSA AP, LEED AP, senior engineer with Vanderweil Engineers, gave a webinar on “Lab Water Systems: Compliance, Treatment, and Sustainability Strategies” as part of Lab Design’s Facilities Management digital event. This multi-webinar series provided attendees with valuable insights into topics related to the fundamental elements of a laboratory's infrastructure, including crucial components such like lighting systems, ergonomics, and water system. From navigating complex environmental laws to exploring innovative solutions for wastewater treatment and water conservation, John’s presentation offered practical strategies to help laboratory planners and designers optimize water management while supporting sustainability goals.

Lab Design News spoke to John about the key takeaways of his presentation, which is available for free on demand viewing here.

Q: Where is the best place to access a state's regulations for laboratory wastewater design, discharge, and treatment?

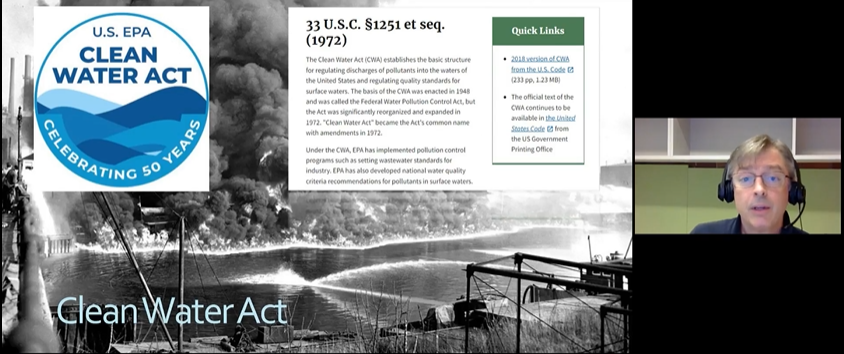

A: Although the overarching regulations that apply across the country stem from Federal Law (i.e. the Clean Water Act as enforced by the EPA), the actual regulation and permitting is handled at either the State or local level (sometimes the regional level as is the case of the Massachusetts Water Resources Authority or MWRA which has jurisdiction over Boston and the greater Boston area). I would recommend starting at the closest resource and working outward if you are looking for specific requirements in your area.

If you are at a facility or campus with an Environment, Health, and Safety (EHS) department, you can contact their environmental compliance officer or the equivalent. Such EHS personnel typically perform various safety and compliance audits anyway and would have the best knowledge about local discharge and treatment requirements.

If you need to look further, I’d suggest you engage the local water treatment utility and ask what their discharge permit requirements are for “categorical discharge” users or “industrial users”. They may have a web site to guide you or at least a number to contact. They may also have application forms online for users who need to apply for a modified or new discharge permit. The application forms and their instructions should specify what their discharge and pre-treatment requirements are. The wastewater treatment utility would be considered the “Authority Having Jurisdiction” or AHJ and typically is the entity that issues you the sewage discharge permit.

Moving further outward, you could search your state’s environmental and wastewater regulations online. You should find the actual legislation text or even a list of the various jurisdictions across the state so you can find the one that you are in.

Keep in mind that in some cases, the regulations between different entities can conflict. This is the case in Massachusetts where the requirements provide opposing directives and the process of getting permit approvals can be hard to navigate. If you find yourself in that situation, you might want to consider engaging an environmental engineering consultant. They can help with the permitting process or do a facility survey to see where you may need to upgrade or modernize existing buildings.

John Rattenbury’s webinar on “Lab Water Systems: Compliance, Treatment, and Sustainability Strategies” is available for free on demand viewing here: https://www.labdesignnews.com/events/facilities-management-webinar-series

Q: For new construction, are there regulations about having sinks inside chemical hoods?

A: I am not aware of specific written regulations that prohibit them, but over the past couple of decades, there has been an evolving interpretation of the containment function of fume hoods. Not only are they intended to provide a negative air space in a lab to carry away harmful vapors, but they should also be capable of containing a minor spill of a hazardous or corrosive chemical. As such, laboratory designers, EHS departments, and local authorities have been prohibiting cup sinks in fume hoods. Where a sink is installed, they would require a one-quarter to one-half inch lip or dam around the sink rim to prevent the overflow of a spilled chemical into the drainage system when the chemical can interfere with or pass through the building pre-treatment system.

Q: Any recommendations for plumbed eye washes and emergency showers?

A: This could be a subject for an entire online webinar in the future. I recently published an article on recommended water delivery temperature to safety showers and eyewashes in Lab Design News.