Designing a Resilient Lab Environment

By: Scott M. Davis,Keith D. Prata,Matthew F. Ezold

Resilience is knowing how to enable change without knowing what that change may be. COVID-19 not only tested the lab design industry’s resilience, but it also tested the resistance of existing laboratory systems and their ability to operate without disruption.

While lab designers have always looked to flexibility as a defining trait of a successful lab environment, the marketability of lab spaces and their ability to hold purpose as new science drives new purpose into labs, means that successful design can be measured by how easily a lab can be changed. Practically speaking, one must understand not only how infrastructure and systems will be installed in lab spaces, but also have a plan for how they will be replaced or augmented in the future.

Discussions on future lab design requirements must start with what lab design professionals were doing well and build on what can be done to reduce the risk of spreading coronavirus and other contaminants throughout the laboratory environment.

Inherent capabilities

Research laboratory spaces have several factors in their favor that make them resistant to the spread of bacteria and viruses, including COVID-19. These include:

Supply air that is comprised of 100 percent outside air

Supply air that is filtered to high levels, typically MERV 13 or better

Spaces are provided with a high volume of air to maintain minimum air change rate of airflow due to the need to control odor and maintain sufficient make up air to devices requiring exhaust airflow, such as fume hoods

Use of containment devices that protect staff and/or the space where work is performed

Spaces are typically under negative pressure, which minimizes cross-contamination between laboratory spaces

Laboratory spaces are kept clean and sanitary to avoid contamination of scientific research being performed

Use of PPE

Because laboratory supply air is made up of 100 percent outside air that is filtered, the air supplied and distributed throughout laboratories—coupled with full exhaust and use of containment devices—provides an environment that minimizes dispersion of contaminates. Good design practice for lab spaces positions supply diffusers and exhaust points (fume hoods, biosafety cabinets, point exhausts, exhaust grilles) to uniformly ventilate spaces they serve, minimizing recirculation of air within the room. The volume of once through air moved through these spaces allows them to be constantly flushed. In comparison, design practices for patient care infectious disease rooms are provided with a minimum of two air changes per hour of air, while laboratories are supplied with six to 12 air changes per hour.

Use of containment devices are implemented to minimize cross contamination. Fume hoods are designed to pull air from behind the operator and down and away from their breathing zone. Biosafety cabinets provide a similar benefit, but also protect the science being performed with the use of HEPA filtration.

Practical/pragmatic system enhancements

Even though laboratories are resistant to the spread of contaminants within their spaces, several measures may be taken to further minimize the probability of releasing and dispersing contaminants, including COVID-19. There are other “add-on” technologies that can be employed to supplement and enhance the laboratory environment and create a positive impact for the lab occupants.

Air filtration

Viruses are very small and can easily pass through air filter media if the virus is independently suspended in the air and not attached/connected to particulate. Bacteria and viruses, including the coronavirus, are often found attached to airborne particulate such as dust, dander, and vapor droplets. These airborne particulates can be readily captured by air filter media; the finer the media capture potential of the filter (the higher the MERV rating), the more dust, dander, and vapor droplets may be captured and removed from the air stream. Air filtration is usually quite easy to install within an existing duct distribution system that may not utilize filtration. Additionally, if the air system already utilizes air filters, these filters can be replaced with higher efficiency filter models.

Bipolar ionization

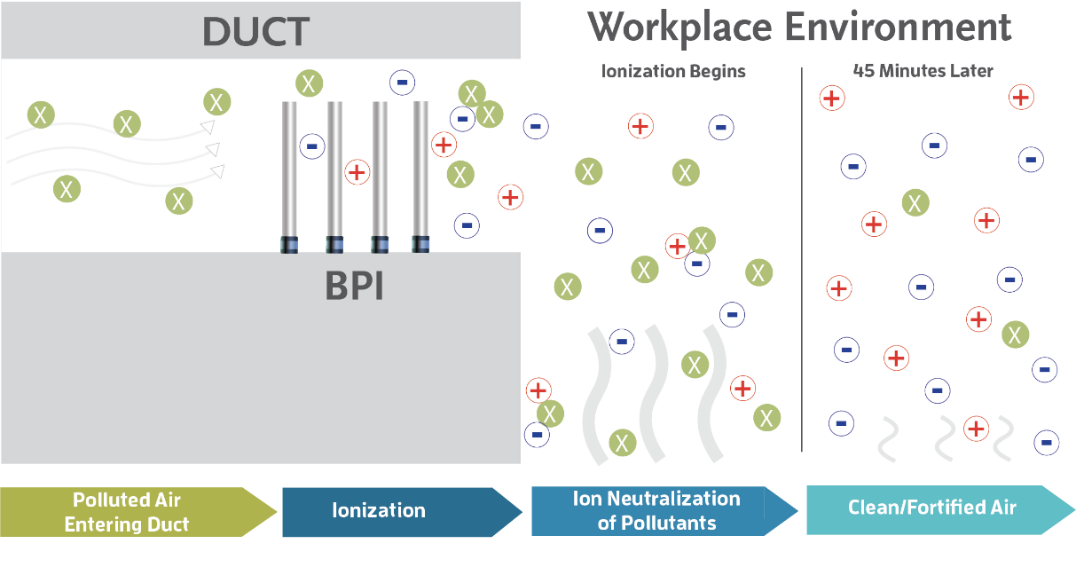

Bipolar ionization process.

BALA CONSULTING ENGINEERS

Bipolar ionization is a proven IAQ technology that may be employed within the supply ductwork distribution system (or in portable air cleaners). This technology creates/generates positively and negatively charged particles called ions. These ions attach themselves to other airborne particulate (such as dust, dander, and vapor droplets), making the particles even larger and thus more susceptible to capture via the air filtration system. Additionally, when the ions come into direct contact with viruses and bacteria, the ions disrupt the surface protein coat of the virus/bacteria and render the organism inactive.

Resilience is knowing how to enable change without knowing what that change may be. COVID-19 not only tested the lab design industry’s resilience, but it also tested the resistance of existing laboratory systems and their ability to operate without disruption.

While lab designers have always looked to flexibility as a defining trait of a successful lab environment, the marketability of lab spaces and their ability to hold purpose as new science drives new purpose into labs, means that successful design can be measured by how easily a lab can be changed. Practically speaking, one must understand not only how infrastructure and systems will be installed in lab spaces, but also have a plan for how they will be replaced or augmented in the future.

Discussions on future lab design requirements must start with what lab design professionals were doing well and build on what can be done to reduce the risk of spreading coronavirus and other contaminants throughout the laboratory environment.

Inherent capabilities

Research laboratory spaces have several factors in their favor that make them resistant to the spread of bacteria and viruses, including COVID-19. These include:

Supply air that is comprised of 100 percent outside air

Supply air that is filtered to high levels, typically MERV 13 or better

Spaces are provided with a high volume of air to maintain minimum air change rate of airflow due to the need to control odor and maintain sufficient make up air to devices requiring exhaust airflow, such as fume hoods

Use of containment devices that protect staff and/or the space where work is performed

Spaces are typically under negative pressure, which minimizes cross-contamination between laboratory spaces

Laboratory spaces are kept clean and sanitary to avoid contamination of scientific research being performed

Use of PPE

Because laboratory supply air is made up of 100 percent outside air that is filtered, the air supplied and distributed throughout laboratories—coupled with full exhaust and use of containment devices—provides an environment that minimizes dispersion of contaminates. Good design practice for lab spaces positions supply diffusers and exhaust points (fume hoods, biosafety cabinets, point exhausts, exhaust grilles) to uniformly ventilate spaces they serve, minimizing recirculation of air within the room. The volume of once through air moved through these spaces allows them to be constantly flushed. In comparison, design practices for patient care infectious disease rooms are provided with a minimum of two air changes per hour of air, while laboratories are supplied with six to 12 air changes per hour.

Use of containment devices are implemented to minimize cross contamination. Fume hoods are designed to pull air from behind the operator and down and away from their breathing zone. Biosafety cabinets provide a similar benefit, but also protect the science being performed with the use of HEPA filtration.

Practical/pragmatic system enhancements

Even though laboratories are resistant to the spread of contaminants within their spaces, several measures may be taken to further minimize the probability of releasing and dispersing contaminants, including COVID-19. There are other “add-on” technologies that can be employed to supplement and enhance the laboratory environment and create a positive impact for the lab occupants.

Air filtration

Viruses are very small and can easily pass through air filter media if the virus is independently suspended in the air and not attached/connected to particulate. Bacteria and viruses, including the coronavirus, are often found attached to airborne particulate such as dust, dander, and vapor droplets. These airborne particulates can be readily captured by air filter media; the finer the media capture potential of the filter (the higher the MERV rating), the more dust, dander, and vapor droplets may be captured and removed from the air stream. Air filtration is usually quite easy to install within an existing duct distribution system that may not utilize filtration. Additionally, if the air system already utilizes air filters, these filters can be replaced with higher efficiency filter models.

Bipolar ionization

Bipolar ionization process.

BALA CONSULTING ENGINEERS

Bipolar ionization is a proven IAQ technology that may be employed within the supply ductwork distribution system (or in portable air cleaners). This technology creates/generates positively and negatively charged particles called ions. These ions attach themselves to other airborne particulate (such as dust, dander, and vapor droplets), making the particles even larger and thus more susceptible to capture via the air filtration system. Additionally, when the ions come into direct contact with viruses and bacteria, the ions disrupt the surface protein coat of the virus/bacteria and render the organism inactive.

Bipolar ionization devices are usually mounted within a supply air ductwork distribution system. These devices require minor amounts of electricity with which to function, and these devices can function during the hours of the usual workday.

UV-C disinfection within air handling unit.

AMCA, INC.; GREEN AIR SOLUTIONS

UV-C lighting

UVGI (ultraviolet germicidal irradiation) is a disinfection method that utilizes short-wavelength ultraviolet lighting to kill microorganisms that are in contact with hard surfaces (or air) that are exposed to the lighting. It is important to note that UV light requires an “exposure time” to kill the microorganisms. As a result, the most effective and practical mounting location for this device is within the evaporator or filtration compartments of the supply air handling unit.

UV-C lights require minor amounts of electricity to function, and these devices can operate during normal business hours as long as they are mounted within the air stream and are not exposed to people.

Pressurization

Controlling and directing air to flow from a low ventilation occupancy (such as office space) toward a high ventilation occupancy (such as laboratory space) offers an added containment attribute for building occupants. By cascading airflow in this manner, the low ventilation air—with higher rates of airborne particulate—can be purged from the building via the laboratory air change rates.

Distribution

Introducing airflow in a nonturbulent downflow pattern will displace air in a uniform fashion, reducing recirculation of air within the space, including any contaminants and particulate that may carry COVID-19. Replacing traditional diffusers with laminar flow diffusers will provide this feature. The use of laminar flow diffusers coupled with exhaust grilles located along the perimeter of the room near the floor (approximately 12 to 18 inches above the finished floor) will further enhance the displacement of room air at low velocity in a downward fashion, sweeping the air to the perimeter of the lab. A similar approach is applied to cleanrooms to minimize recirculation of contaminants that are introduced within the space.

Hands-free fixtures

The use of hands-free fixtures within laboratories is another measure to reduce the potential of spreading contaminants. Hands-free fixtures may be activated via wrist blades, knee and foot pedals, or motion sensors.

Laboratories may not always incorporate these types of fixtures, but they may be retrofitted into existing spaces if necessary. If hands-free fixtures are not a viable option for financial or spatial reasons, the use of disposable gloves will achieve similar results by preventing contact between hands and surfaces.

Relative energy costs.

BALA CONSULTING ENGINEERS

Energy impacts

When considering enhancements to the air distribution systems, it is important to be aware that these measures will require additional energy and will increase operational costs. The chart below demonstrates the relative impact to energy and operational costs for different strategies. Increasing filtration from MERV 13 to HEPA filters, or adding bipolar ionization or UVC lamps has minimal impact to operational costs. Although laboratories are typically humidified to 30 percent RH, increasing humidity levels to 40 percent RH will require significantly more energy and increase operational costs.

Technology resilience

Before the intersection of biology and technology drove an increased need for data capacity in lab spaces, labs were working to improve available Internet carrier options and bandwidth capabilities to meet the demands of visualization, sequencing, and simulation systems. While local server rooms may always have a place for zero-latency applications and hardware testing use, the pairing of in-person lab space with offsite data storage and virtualized application platforms will be a key element of lab resiliency. Multiple Internet carrier options, entrance facility diversity and redundancy, and a building riser prepared to easily distribute and upgrade fiber cabling direct to on-premises testing platforms allows precious building square footage to be dedicated to in-person experimentation and reduces back-of-house support needs. This focus on a lab built to bring people to their science and offload processing and storage to spaces built for computing is another key driver to resiliency.

Resiliency requires awareness of your space and the metrics necessary to make informed decisions. COVID-19 has accelerated the use of IoT sensors and environmental information gathering by putting a focus on the ability to collect and trend data across multiple sites—often done outside of the information being provided by traditional building management platforms. The ability for tenants to gather and trend environmental data, separate from the high-level information provided by landlord systems, and the ability to merge occupant data with building data provides a much more holistic understanding of how the working environment is impacting users—and how they in turn react. Lab designers can now look at the utility of a space based on occupancy, demand, environmental comfort, and safety as a single effort.

As a result of COVID-19 technology acceleration, lab spaces will also benefit from common workplace technology changes. Increased use of remote collaboration technologies, visitor management systems, mobile access controls, space sensing platforms, and other workplace productivity systems have applications in lab environments. These platforms can be used to help ease the movement of staff across multiple sites, connect remote administrative staff who do not have critical in-person requirements, and allow teams working in remote locations to collaborate as a single cohort.

Moving forward

While the next pandemic can’t be predicted, or even the final outcomes of the current one, lab design professionals can take away some key lessons from the purpose-driven triage and remediation work that have happened in laboratory facilities over the last two years. Lab spaces are inherently resistant, but must be resilient to maintain alignment with constantly changing requirements and science.

Though lab spaces are inherently resistant to the spread of contaminants, additional technologies may be applied to further protect occupants. Application of smart building technology and related analytical software will enhance this effort. In addition, lab designers can look to workplace technologies that may be applied to the laboratory environment to further reduce the potential of spreading contaminants by reducing exposure between personnel.

Implementing these strategies will impact energy and costs. Facility and lab managers will need to understand these measures and plan for their ongoing maintenance as well as incorporate them into their operational budgets.

Understanding the specific capabilities of their existing laboratories, lab managers may evaluate the ability of their spaces to minimize the spread of contaminates and increase resilience. Decisions can then be made about which strategies to implement to reduce the potential spread among personnel and best meet the financial- and purpose-driven goals of the facility.

Scott M. Davis, PE, LEED AP, is director of mechanical engineering; Keith D. Prata, PE, LEED AP, is mechanical department manager; and Matthew F. Ezold, CTS-D, is director of digital planning, all with Bala Consulting Engineers in King of Prussia, PA.