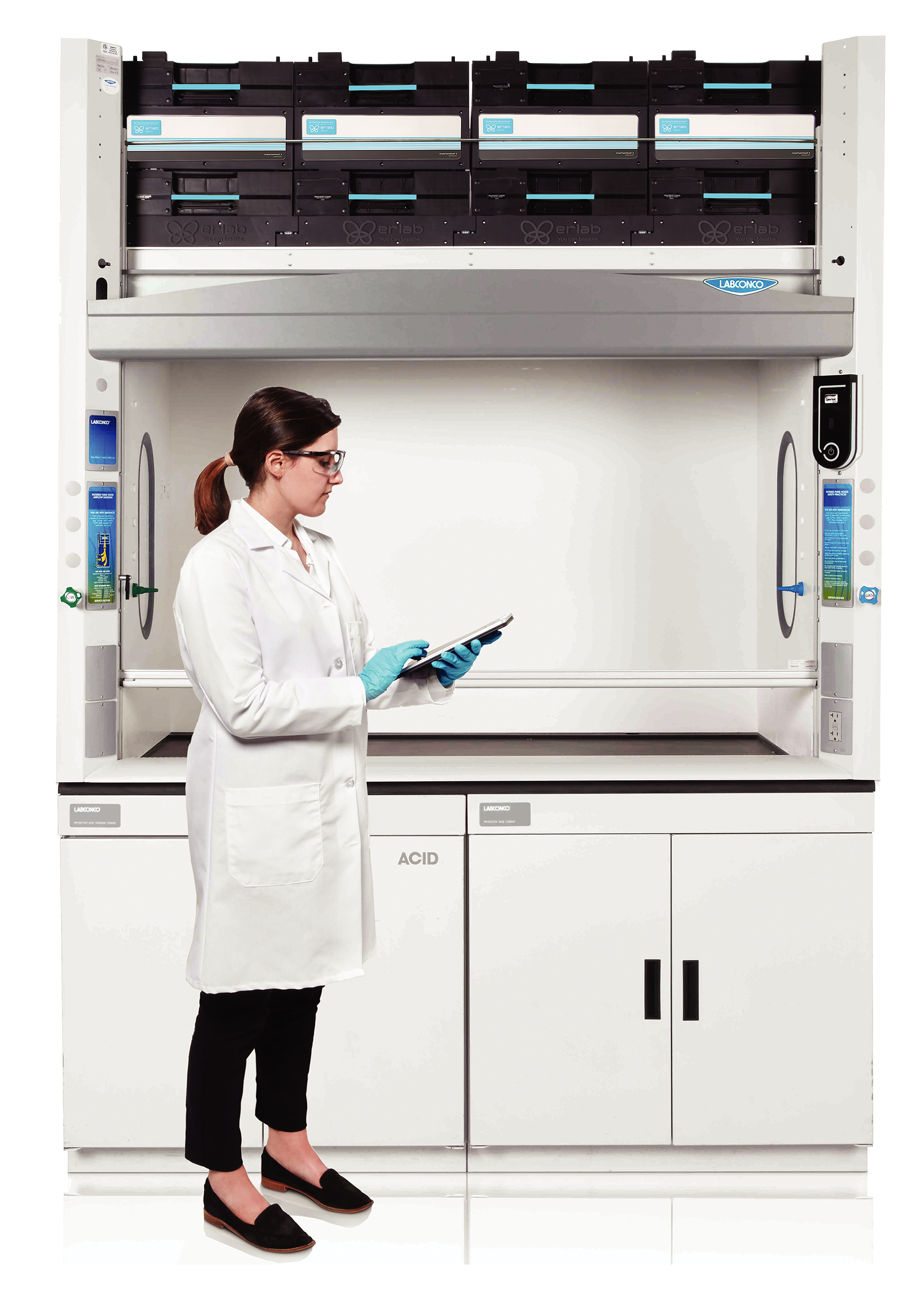

Debunking the Dangers of Ductless Filtering Fume Hoods

Source: Erlab

Fume hoods are crucial tools in laboratories, providing a safe environment for researchers to work with hazardous substances. Traditionally, fume hoods have utilized ducted systems to exhaust toxic fumes outdoors. Ductless filtering fume hoods, however, have emerged as an alternative solution that eliminates the need for costly ductwork and offers flexibility in lab design and, more importantly, a safe solution with substantial reductions in the environmental impact. Despite their benefits, some misconceptions surrounding the safety and effectiveness of ductless filtering fume hoods persist. In this article, we will debunk these concerns and highlight the advantages of this innovative technology.

Understanding ductless filtering fume hoods

Ductless filtering fume hoods are self-contained units that employ a combination of filtration technologies to capture and remove hazardous fumes, vapors, and particulates from the air within a laboratory. These hoods utilize high-quality filters, such as activated carbon and HEPA (high-efficiency particulate air) filters, to trap and neutralize contaminants effectively before recirculating the purified air back into the laboratory.

Source: Erlab

Dispelling concerns about air contamination

One common misconception is that ductless filtering fume hoods may lead to the contamination of the laboratory environment. Ductless hoods, however, are equipped with multiple layers of advanced filtration media that effectively remove hazardous substances from the air. The activated carbon filters used in ductless hoods are highly efficient at adsorbing a wide range of volatile organic compounds (VOCs) and chemicals, ensuring that the air released back into the lab is clean and safe to breathe.

Additionally, HEPA filters in ductless systems capture particulates, including dust, bacteria, and other microorganisms, further enhancing air quality. The combination of these filters provides an effective barrier against potential contaminants, dispelling concerns about air pollution within the laboratory.

However, not all ductless fume hoods are created equal, and you must validate the manufacturer to ensure they comply with appropriate safety standards and are able to deliver a DFH III fume hood, which means that there are always two layers of carbon filtration of the same media, sensors to detect a potential spike in concentration released at the main carbon filters exhaust and means of communication.

Addressing safety and fire hazards

Another concern—or, more appropriately, misconception—is the possible flammability risk associated with the filters. As ambient air is continuously introduced to the filter media, there is never a sudden introduction of oxygen, coupled with low-level ppm of adsorption, which avoids the risk of flammability. However, always make sure the manufacturer provides a thorough analysis of the chemical handling to ensure all safety criteria are met. This can include, if required, a study of the maximum LEL percentage that could be present within the enclosure based on the chemical handlings, further eliminating any concerns or risks.

Moreover, ductless filtering hoods undergo rigorous testing and certification processes to ensure compliance with safety standards. Independent testing organizations evaluate these hoods to verify their performance, including their ability to contain hazardous substances and prevent the release of harmful fumes. These certifications provide reassurance regarding the safety of ductless filtration hoods.

Enhancing efficiency and cost savings

Source: Erlab

Ductless filtering fume hoods offer significant advantages in terms of energy efficiency and cost savings. Unlike traditional ducted systems, which require significant installation and maintenance expenses, ductless hoods eliminate the need for complicated ductwork. This streamlined design reduces upfront costs and allows for greater flexibility in lab layout and relocation.

Furthermore, ductless filtering hoods are equipped with energy-efficient motors consuming a maximum output of 260 watts and are equipped with safeguards to ensure optimal performance, so safety is never compromised.

Conclusion

Ductless filtering fume hoods provide a safe and effective alternative to traditional ducted systems. By dispelling concerns surrounding air contamination and fire hazards, it is evident that these hoods offer a reliable solution for laboratories. With advanced filtration technologies, safety features, and certifications in place, ductless filtering fume hoods not only ensure the protection of laboratory technicians but also enhance energy efficiency and cost savings. Embracing these innovative hoods can lead to safer, more sustainable laboratory environments.

Jesse Coiro leads Erlab as Director of NA Operations, overseeing the company's strategic vision, product development, and operations.

Founded in 1968, Erlab designs and manufactures sustainable ventilation solutions for the scientific research industry. Under Jesse's leadership, Erlab has emerged as an innovation leader in filtered fume hood technologies that enable significant energy savings for labs.

Erlab is at the forefront of chemical filtration technology, offering a range of ductless fume hoods, filtered storage cabinets, and air purifiers. Their green, sustainable solutions protect laboratory personnel from exposure to harmful chemicals while improving the environmental footprint of laboratories.