Cutting Carbon: New Tools to Reduce Carbon Emissions From Laboratories

By: Dirk von Below, Flad Architects and Jacob Werner, Ellenzweig

Decarbonization is more than just a buzzword—it has become a top design requirement for the research facilities of tomorrow. And it's not just about reducing carbon emissions from energy use. Reducing embodied carbon, or the emissions generated during the production and transport of construction materials, is increasingly a concern for building owners and designers. Building construction is estimated by the World Green Building Council to be responsible for 11 percent of global carbon emissions, with no sign of slowing.

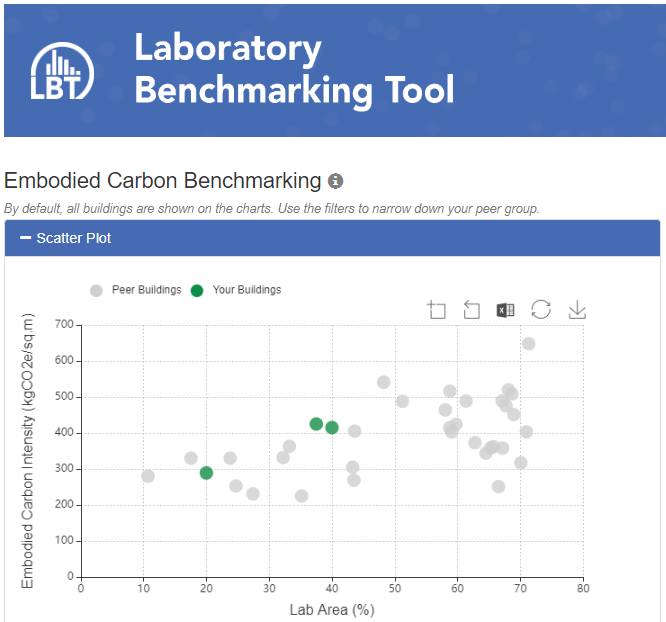

That's why the International Institute for Sustainable Laboratories' (I2SL's) Labs2Zero initiative has begun measuring embodied carbon associated with lab construction and major renovations. Using life cycle assessment (LCA) data submitted by industry volunteers, the I2SL Lab Benchmarking Tool has expanded from rating lab buildings' energy and operational emissions performance to include embodied carbon data from lab building construction. The data covers the "cradle-to-gate" life cycle stages known as A1-A3 (i.e., raw material extraction, transportation of raw materials, and product manufacturing) for materials used to build lab structure and enclosure/shell building components (e.g., concrete, steel, masonry, aluminum, wood, insulation, cladding, glass).

LBT users can now benchmark lab buildings (existing or in design) against selected peer group buildings with similar characteristics, including functional and structural requirements. Once sufficient LCA data has been received for statistical analyses, I2SL plans to develop an Embodied Carbon Score as part of its Labs2Zero tools, including a pilot Operational Emissions Score for lab buildings (see sidebar below).

The LBT is the largest database of laboratory building energy use, categorized by building size, laboratory function, owner type, and location. Now, the database includes the largest known collection of laboratory-embodied carbon data. In addition to being large, robust, and free to use, the LBT anonymizes building data so that identifying aspects are not visible to other users. I2SL hopes that this free, secure tool will entice owners and designers to benchmark buildings, assess the carbon impact of their projects, and ultimately reduce the emissions associated with lab construction.

Why Benchmark Laboratory Embodied Carbon?

When ranking a lab building's emissions—whether operational or embodied carbon—it's important to compare with other labs. Lab buildings have unique technical specifications, which may require a more substantial building structure, more resource-intensive finishes, and more energy use than other building types. In particular, the following lab building design considerations can translate into higher embodied carbon:

Building/ceiling height. Labs are built to accommodate unknown future use and more intensive mechanical systems, often located in the ceiling, interstitial floors, or mezzanines. Taller buildings must also provide higher wind resistance, resulting in additional structural materials.

Stiffer and heavier structures. Labs are built to resist vibrations and bear the weight of heavy machinery, casework, and equipment.

Requirements for retrofit. Renovating or adapting buildings to meet lab-specific requirements—such as floor height and load capacity—can be more costly.

Unique lab requirements. Radiological, biological, physical science, computing, and engineering research labs require more space, more substantial construction, more complex mechanical systems, and specific types of finishes. This equates to more embodied carbon.

By collecting embodied carbon data from lab structures, I2SL hopes to better understand the drivers of carbon intensity in laboratory construction and suggest strategies for reducing emissions.

How Do We Reduce Laboratory Embodied Carbon?

First, consider site selection and adaptive reuse of existing building assets. These are the most impactful strategies to reduce carbon generation associated with lab construction. For example, Northwestern University, working with Flad Architects on Mudd Hall, reduced embodied carbon by 40 percent by converting an existing library building into a new, highly sensitive physics laboratory. The project achieved this dramatic carbon savings by reusing the building structure and the existing roads, parking, and utility networks.

Northwestern University renovated an existing library building into a 188,000-square-foot laser laboratory by reusing the existing building structure, which reduced the embodied carbon of the building materials by 25 per cent.

Next, consider the materials used in the lab structure and whether they can be reduced or selected for lower embodied carbon. Reducing the building mass or weight from concrete, metals, or glass will reduce associated carbon emissions and costs. This means that optimizing the building structure, reducing moment frames, saving space, and lowering floor-to-floor height are all potential opportunities to reduce the building's carbon footprint. An LCA will help you calculate carbon equivalent emissions per kilogram of each material.

Some industry initiatives, such as the EC3 Tool, aggregate embodied carbon data for materials used in construction. The tool makes it easier for designers and builders to identify innovative, low-carbon technologies and products. Innovative concrete materials such as supplementary cementitious materials (SCMs), ground glass pozzolans, and carbon sequestering concrete significantly reduce the carbon associated with traditional concrete mixes. Steel products with more than 90 percent recycled content also have significant carbon benefits. Moreover, the U.S. Environmental Protection Agency is working on a label for construction materials (e.g., steel, concrete, asphalt, and glass) that demonstrate lower embodied carbon through their environmental product declarations (EPDs).

By measuring and benchmarking lab buildings, we will better understand the research enterprise's carbon footprint. Then, as sustainable designers and lab owners, we can work to reduce labs' impact on climate change. By building a broader and more inclusive lab carbon dataset, we can also help create a more resilient built environment.

SIDEBAR 1:

New Operational Emissions Score Available for Lab Buildings

The Labs2Zero pilot Operational Emissions Score compares the greenhouse gas emissions from an individual lab building with those of its peers. The score is calculated using facility energy consumption data, including onsite renewable energy, along with emission factors for the building's local electrical grid and all other energy utilities.

The score is a 1-100 percentile ranking, so a score of 75 means the operational emissions performance of that building is better than 75 percent of its peers in the LBT database. You can get an Operational Emissions Score for an existing lab building or validate emissions results expected from a new lab project design for free by entering data in the I2SL Lab Benchmarking Tool.

The pilot Operational Emissions Score is a location-based score, which means it does not take into account market-based purchases of renewable energy certificates (RECs), green power, energy attribute certificates (EACs), and green tariffs. I2SL encourages LBT users to enter data on these types of renewable energy purchases for lab buildings they support now, as a market-based score is planned for the future.

SIDEBAR 2:

A Mass Timber Lab at Michigan State

Completed in 2021, the STEM Teaching and Learning Complex at Michigan State University is a new, dynamic hub for science education comprised of two new teaching lab wings, an entry atrium/classroom addition, and the adaptive reuse of a decommissioned power plant. Supported by Ellenzweig, it is the first large-scale mass timber project in Michigan; the new STEM wings employ glue-laminated and cross-laminated timber (CLT) for the building structure, decks, and shear walls. A new floor area inside the power plant was created with structural CLT floor panels on new and existing steel framing. A conventional steel frame for the STEM wings would have required 24 times the embodied carbon needed for fabrication than a timber frame. The mass timber components sequester 1,856 metric tons of carbon dioxide emissions.

Jacob Werner, an associate principal with Ellenzweig, is a senior architect and laboratory planner who has devoted his career to designing intuitive environments for scientific discovery. Jacob holds credentials as a LEED AP BD+C, WELL AP, Living Future Accreditation, and Passive House Consultant and has contributed to I2SL’s best practices guides on decarbonizing laboratories and lab decarbonization.

Dirk von Below, AIA, LEED AP BD+C, is a project manager at Flad Architects and a member of the I2SL Labs2Zero Leadership Council. He has over 30 years of comprehensive architectural experience delivering science buildings to private and institutional clients, balancing state-of-the-art design, efficiency, and environmental considerations within a tight financial framework.